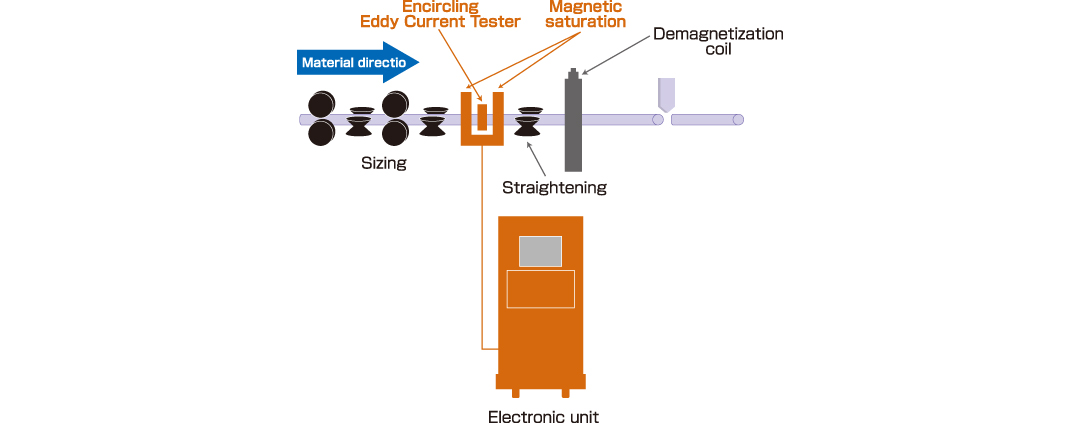

This is a testing system for surface inspection for the products not only at the final stage of production of steel or nonferrous metals, but also hot roll which is in the process.

This system is appropriate for detecting the flaw which has a surface area such as scab and pinhole. Detect the flaw by make tested material pass through encircling hole of coil.

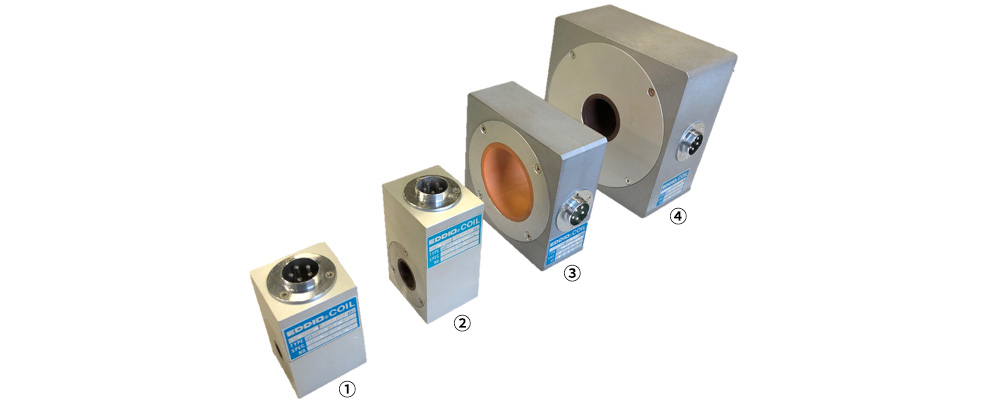

Our encircling coil are winded by hands of skilled staff. All process can be done in our company such as designing, manufacturing, and adjusting. Therefore customized coils can be produced according to customer's demand.

Those which are introduced in above are main coils. There are coils that can be used for various size of dimeter, shape, or individual specifications. Therefore, please feel free to contact us.

| ① | ② | ③ | ④ | |

|---|---|---|---|---|

| FN-2A | SN-2A | FN-3A | FN-4A | |

| Size(mm) | W 50 x H 80 x D 50 | W 50 x H 100 x D 50 | W 50 x H 120 x D 120 | W 80 x H 160 x D 160 |

| Material diameter(mm) | φ3-φ14 | φ3-φ20 | φ3-φ60 | φ40-φ70 |

| Type | Self-induction self-comparing type/ Mutual induction self-comparing type | |||

| Auxiliary winding | Auxiliary winding is selectable ※Auxiliary winding: It contributes S/N ratio by reducing noise from the vibration |

|||

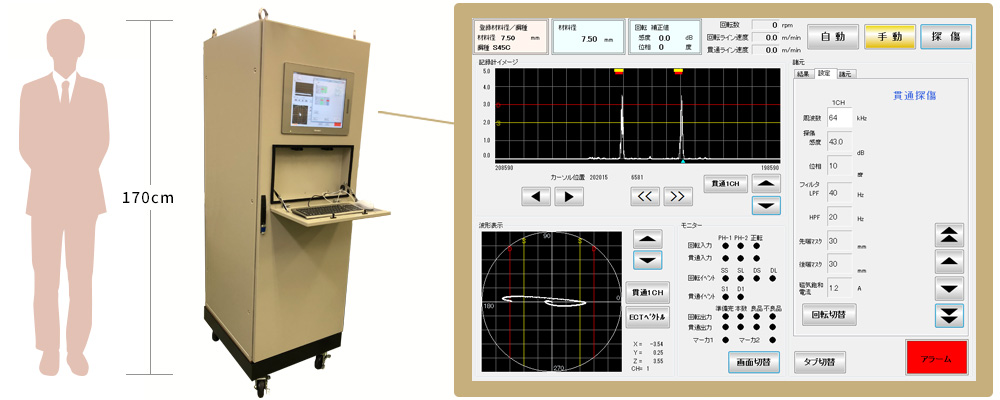

| Features | ||

|---|---|---|

| Saving detection parameter | Recordable and replayable detection waveform | Excellent simplicity and operability of interface |

| Possible to be used with rotational eddy current tester | Phase gate evaluation | Built in self-diagnostic system |

| Touch panel is available | ||

| Size(mm) |

|---|

| W 600 x H 1710 x D 1010 |

| Weight(kg) |

|---|

| About 330* *Weight is subject to be changed, depend on the specification |

The case of pipe mill line

Magnetic saturation device

In order to carry out flaw detection for magnetic material, magnetic saturation device is needed to use together in some cases. There is various types of magnetic saturation device in our product line for meeting many types of tested materials, and conveyer lines Therefore, please contact us. Please be notified that if you use magnetic saturation device, demagnetizing device may be also needed.